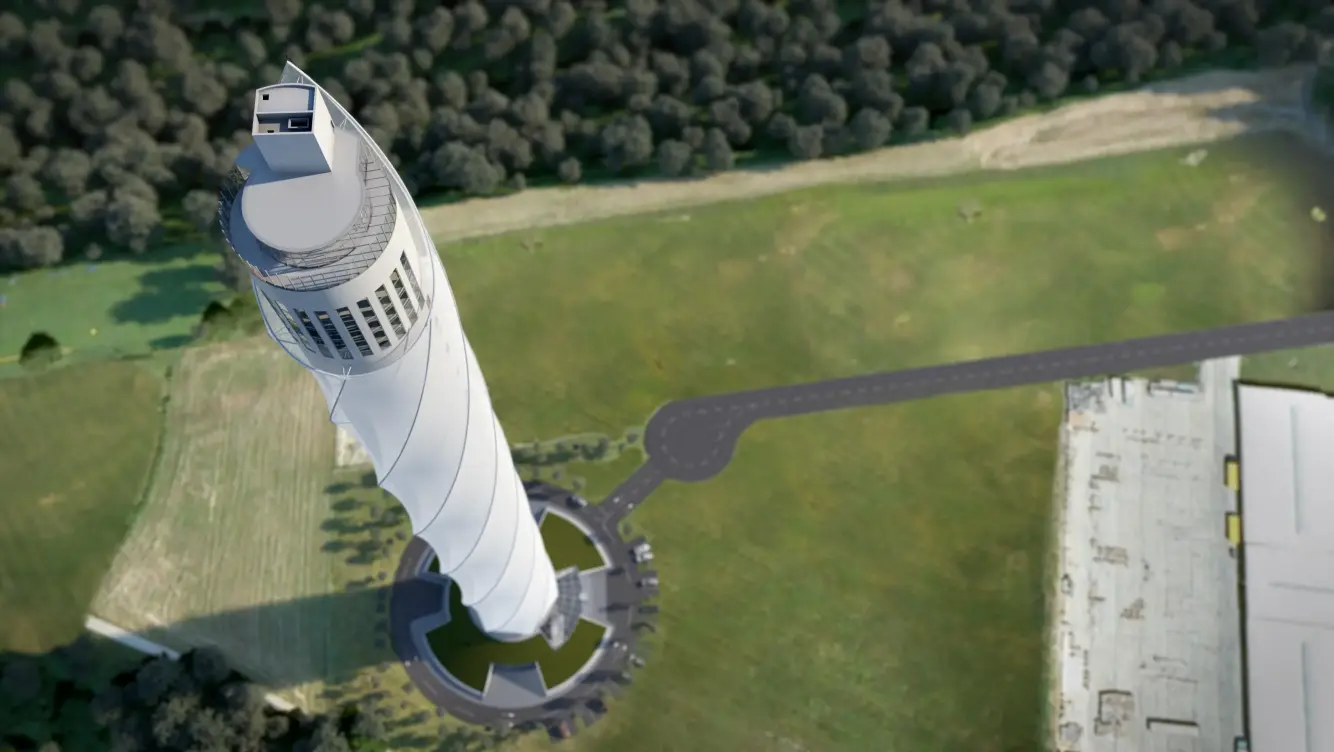

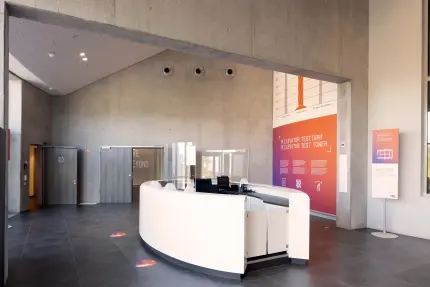

Enjoy a breathtaking 360-degree panoramic view from the public visitors’ platform. If the weather is good, you can see all the way to the Alps.

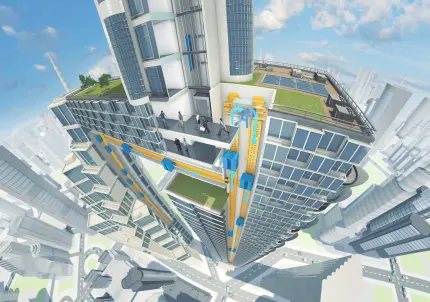

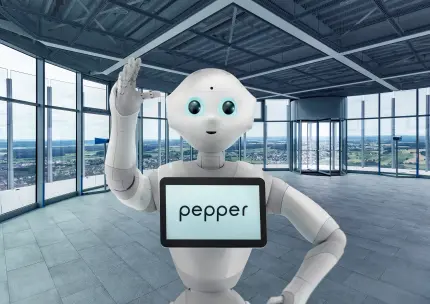

The 246-meter tall elevator-testing tower, opened in 2017, is specifically designed with the future in mind: With 12 testing shafts housed within its 21-meter diameter shell, engineers can test elevators at dizzying speeds of up to 18 meters per second. The tower firmly places Rottweil at the very hub of future urban vertical transportation.

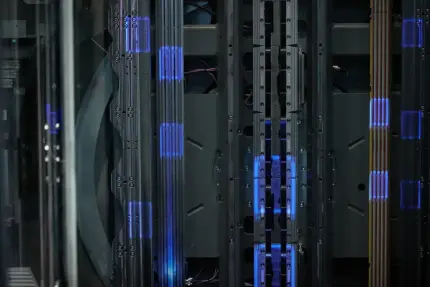

Three shafts, each of them with a height of 100 meters, are dedicated to testing the innovative new MULTI systems. The MULTI elevator is the realization of a dream for operating multiple cabins simultaneously. It introduces mag-lev train technology to the elevator industry, increases shaft transport capacity by up to 50 percent, and dramatically reduces the elevator footprint in buildings.

Test tower

Test tower